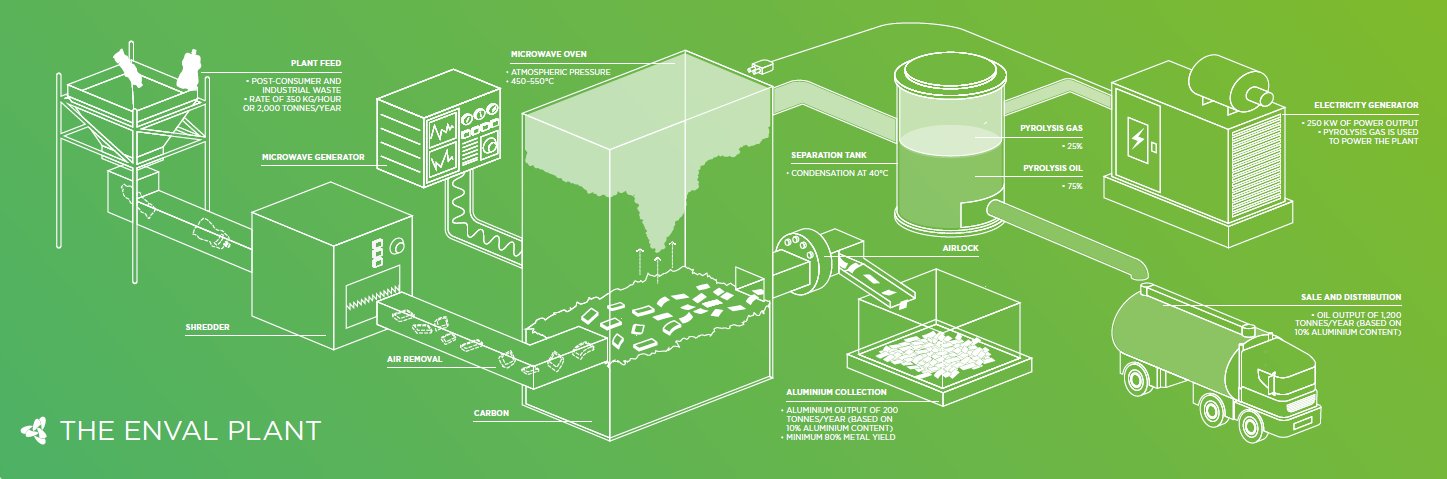

THE ENVAL PROCESS

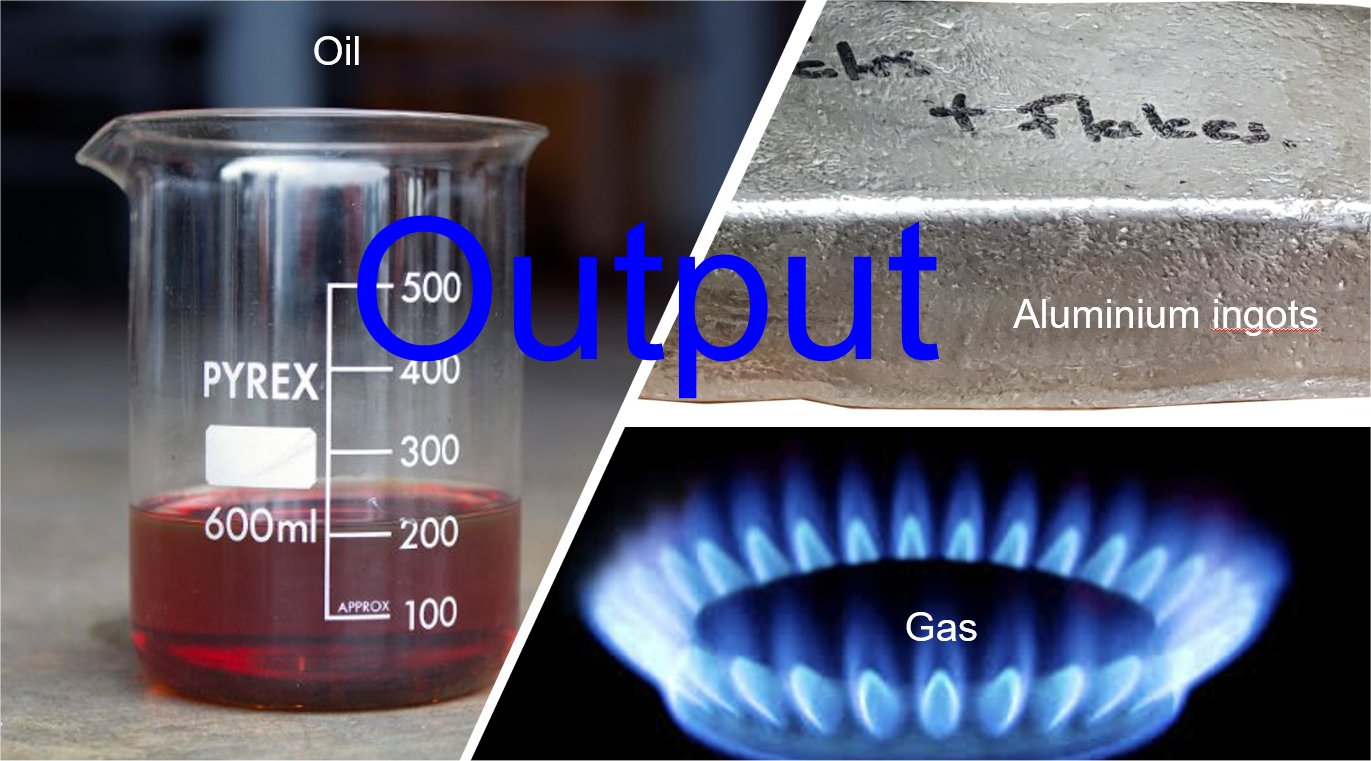

Enval has created a unique solution for recycling plastic aluminium laminates using microwave induced pyrolysis. Our process is clean, efficient and economical for both post-consumer and industrial waste. The benefit from this new self-driven recycling system with plastic aluminium laminate is Aluminium ingot, Oil and Gas. Contact SmartFoodPack and we will help you through the process.

More info on the process her: www.enval.com/process

Contact Engskov Emballasje AS for international sales: post@engskovemballasje.no

Aluminum Recycling

Recycling is very important to sustainable development. It allows resources to be saved and waste to be reduced.

Read more from HYDRO here

History of aluminium

- Aluminium was discovered relatively late – in 1807.

- Years were spent on trying to extract the metal from its ore, and the

Danish physicist and chemist Hans Christian Ørsted was the first

one in 1825 to succeed. However, the manufacturing costs were so

immense that it for many years exceeded that of gold. - As a start, Aluminium was mainly used to make pieces of jewellery.

- Today, the processes have been further developed, and aluminium is

used in many sectors – fx in transport, building, construction, electrical

engineering and packaging sector.

Aluminum laminat consists of 60-70% pure aluminum and it’s the most recycled and sustainable metal today. Producing recycled aluminum is 92% more energy efficient than making new aluminium, and nearly 75% of all aluminum ever produced is still in use.